Residential Solar Installation: Everything You Need to Know

Your Solar Roadmap: Why It Matters and What This Guide Covers

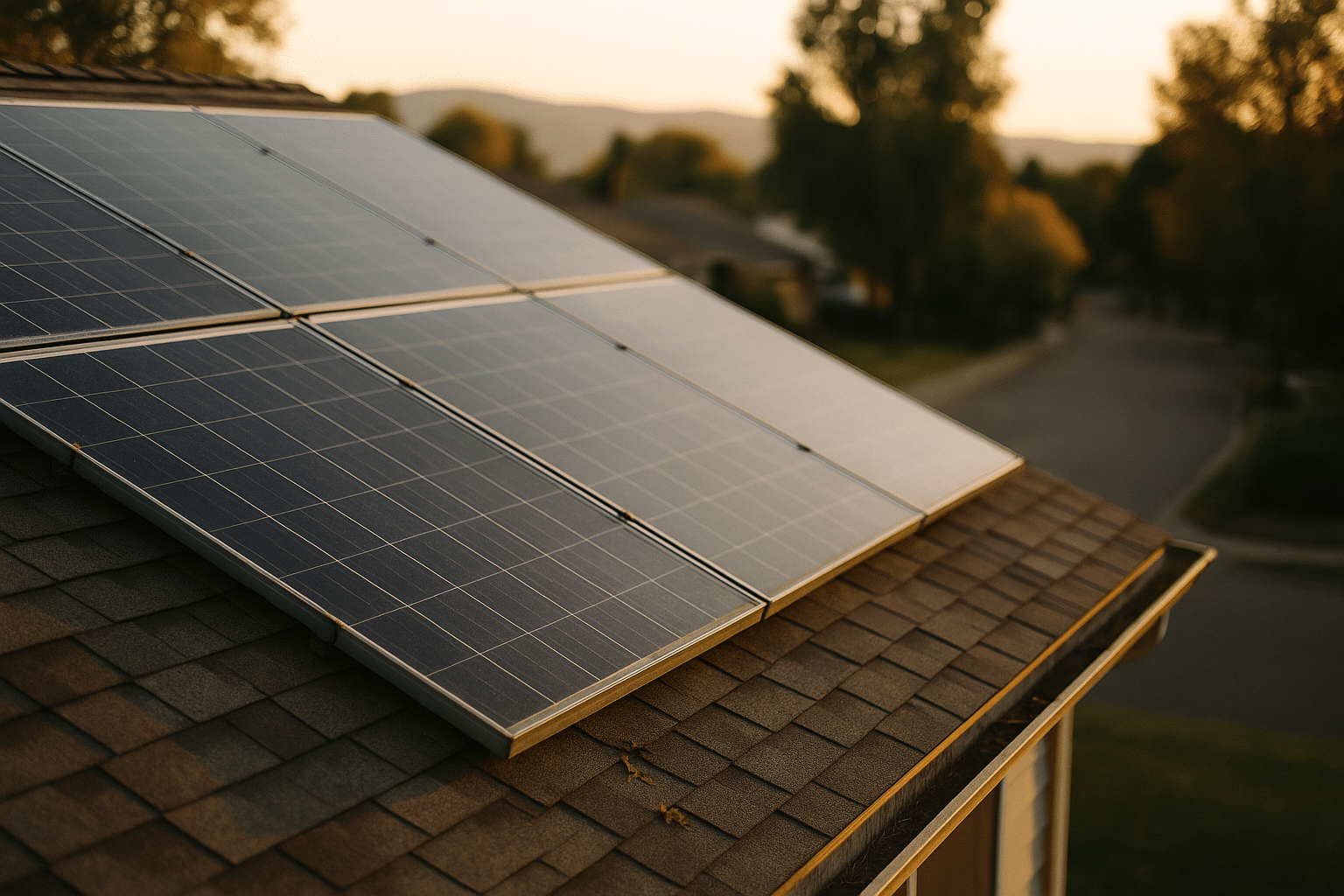

Residential solar is a practical way to cut electricity bills, reduce exposure to rate hikes, and lower household emissions. For many homes, a well‑designed system turns an idle roof into a quiet power plant that works whenever the sun rises. The aim of this guide is to replace mystery with clarity, supplying the context and numbers you need to make a grounded decision. Before we dive deep, here’s the outline so you can skim to what matters most and see how the pieces fit together.

– Section 1: A roadmap and context for why solar matters, plus what this guide covers.

– Section 2: Cost ranges, incentives, payback math, and financing paths.

– Section 3: Equipment choices (panels, inverters, batteries, racking) and design trade‑offs.

– Section 4: Site assessment, permits, inspection, interconnection, and safety.

– Section 5: Operation, monitoring, maintenance, and a concise conclusion to help you take next steps.

Why is this relevant now? Electricity prices in many regions have trended upward over the last decade, and homes are increasingly electrifying heating, water heating, and transportation. A typical household might use 8,000–12,000 kWh per year; in many climates, 1 kW of solar capacity can produce roughly 1,200–1,700 kWh annually, depending on roof tilt, azimuth, shading, and local weather. That rough ratio means a 6–8 kW system often offsets a substantial share of usage for a medium‑sized home. Solar also distributes energy generation closer to where it is used, which can help grid resilience, especially when paired with storage that supplies backup power during outages.

Of course, solar is not a one‑size‑fits‑all purchase. Suitability depends on roof condition, available sun, local incentive structures, and how your utility credits exported energy. Good projects start with honest constraints: roof age and structure, shade from trees or chimneys, and the economics of your utility tariff. In the pages ahead, you’ll see how to turn a site assessment into an actionable design, read proposals with confidence, and understand the installation and approval sequence so you know what to expect. Think of this as a map: you can follow it end to end, or jump to the section that answers today’s question.

Costs, Incentives, and Payback: Making the Numbers Work

Costs vary by region, labor market, equipment selection, and project complexity, but national averages provide a useful frame. Many residential systems land around $2.50–$4.00 per watt before incentives; a 6 kW system at $3.00/W has a gross price near $18,000. A 10 kW system at $2.80/W is roughly $28,000. Incentives can materially change that picture. A federal income tax credit has been set at 30% for qualifying residential solar and many battery systems within recent policy windows, reducing the net outlay if you have sufficient tax liability. Some states or utilities offer rebates (often a fixed $/W or a flat amount), performance credits for each kWh generated, or property‑tax considerations. Local programs can be stackable, but each has rules about eligibility, interconnection timing, and documentation.

How do you translate price into payback? Start with your avoided utility cost: multiply expected annual production by your marginal rate (including energy, delivery, and riders). Consider how your utility credits excess generation. Net metering can credit exports at or near the retail rate, while other structures may credit at a lower rate or on time‑of‑use schedules. These policies affect effective savings and payback length. In many markets, simple payback falls in a 6–12 year range; that spread reflects sun levels, incentives, installed cost, and tariff details. To stress‑test a proposal, model utility rates rising modestly (for example, 1–3% annually), and evaluate scenarios for sunny, average, and cloudy years.

– Cash purchase: highest lifetime savings, immediate ownership, no interest costs.

– Loan: smaller upfront payment, fixed monthly amount; compare APR, fees, and prepayment terms.

– Lease or PPA: low upfront cost and predictable payments; savings depend on escalators and energy crediting rules.

– Add‑on storage: raises upfront cost but can increase self‑consumption and provide outage protection; value depends on tariff and backup needs.

Look beyond the headline price. Review workmanship and equipment warranties, roof work allowances, and potential service fees. Ask for a production estimate that discloses key assumptions: system size (kW DC), expected kWh in year one, degradation rate, shading losses, and module orientation. Request a sensitivity table showing savings if production is ±10% from the forecast. If proposals show dramatically different outputs for similar designs, probe the underlying assumptions rather than the promise. A transparent, conservative forecast is often a better guide than an optimistic curve that is hard to reproduce.

Equipment and Design Choices: Panels, Inverters, Batteries, and Mounting

Solar equipment decisions influence price, production, aesthetics, and maintenance. Today’s mainstream modules are monocrystalline, with typical nameplate efficiencies around 19–22% and product warranties commonly spanning 12–25 years. Performance warranties usually guarantee that output will remain near 84–92% of the original rating by year 25, implying average degradation rates roughly 0.3–0.7% annually. Higher‑efficiency modules can help when roof space is tight, though the premium per watt may not always be justified if you have ample area. Black‑framed or all‑black modules can blend with certain roofs, trading a little thermal performance for aesthetics in hot climates.

Inverter topology shapes system behavior. String inverters centralize conversion and can be cost‑efficient, but strings are limited by the lowest‑performing module in shade unless paired with DC power electronics. Module‑level electronics allow each panel to operate more independently, improving yield on complex roofs and enabling rapid shutdown functions. Hybrid inverters support batteries on the same platform, simplifying storage integration. When comparing designs, consider the ease of service: a single central unit is simpler to replace, while distributed electronics can isolate failures to one module. Examine warranties—10–12 years for many string inverters with options to extend, and 20–25 years commonly offered for some module‑level devices.

Storage decisions start with intent. If you want backup, estimate essential loads and hours of coverage; many homes size for 5–20 kWh per battery bank, with more required for extended outages or whole‑home backup. Lithium iron phosphate chemistries are widely used for their cycle life and thermal stability. Value depends on your tariff: time‑of‑use billing and demand charges can improve economics by shifting solar energy into peak periods. If your utility credits exports generously, storage may be primarily about resilience rather than bill savings.

Mounting hardware and roof interface are the unsung heroes. On asphalt shingles, flashed and sealed penetrations protect against leaks; on standing‑seam metal, clamp‑on systems can minimize penetrations. Tilt angles near the site latitude often maximize annual yield, but roof slope and wind/snow considerations influence choices. Setbacks along ridges and hips preserve firefighter access. Ground mounts or carports offer excellent airflow and maintenance access if you have space. A thoughtful layout balances output, appearance, and serviceability—and it starts with a realistic map of sun, shade, and the roof’s strongest areas.

From Site Assessment to Permission to Operate: The Process, Permits, and Safety

A smooth project follows a clear sequence. It begins with a site assessment: measure roof planes, document obstructions, and check the main electrical panel for available capacity. If the roof is near the end of its life, factor in replacement before solar, which avoids the cost of removing and reinstalling the array later. Engineers verify structure and wind/snow loads, and designers model sun paths through the seasons. The design package includes a one‑line electrical diagram, roof layout, equipment specs, and labels. Local building and electrical permits, along with utility interconnection applications, are submitted in parallel where possible.

Timelines vary by jurisdiction. Simple residential permits can be approved in a few days; more complex areas may take several weeks. The actual installation generally takes 1–3 days for standard rooftop systems, followed by inspections and utility meter work. Only after passing inspection and receiving utility authorization will the system be allowed to operate in parallel with the grid. Plan for temporary disruptions: power may be off for portions of a day, and driveway access might be needed for staging materials.

Electrical and fire safety are central. Modern systems incorporate rapid shutdown capabilities, grounding and bonding, arc‑fault protection, and labeling to help first responders. Roof work uses fall protection and secure anchor points; penetrations are flashed and sealed to shed water. Conductor sizing, overcurrent protection, and busbar calculations must satisfy code, including the commonly referenced 120% rule when backfeeding the main panel. For homeowners, a pre‑job checklist helps set expectations and prevent surprises.

– Clear the attic access for structural inspection.

– Trim vegetation that shades key roof planes if appropriate.

– Identify essential circuits if you plan to add a backup panel.

– Confirm Wi‑Fi coverage at the inverter location for monitoring.

– Keep documentation handy: permits, approved plans, and interconnection paperwork.

Quality control doesn’t end on install day. Expect commissioning tests that verify string voltages, inverter operation, and monitoring connectivity. A thorough handoff includes as‑built drawings, serial numbers, and warranty registration. Don’t be shy about asking for a walkthrough of the roof array, conduit paths, and shutoff locations so you know the system as well as the crew that built it.

Operations, Monitoring, and Next Steps: Owning Solar for the Long Haul

Once your system is live, attention shifts from construction to performance. Monitoring portals display production by day, month, and year, often alongside or integrated with consumption data if a meter is included. In the first weeks, compare actual output to the proposal’s month‑by‑month forecast. Expect seasonal swings: winter sun sits lower and days are shorter, while summer brings longer, brighter days. Dust, pollen, and snow can reduce output temporarily. Light rain usually cleans modules; in dusty regions, a gentle rinse during cool hours can help. Avoid abrasive tools or high‑pressure jets that could damage glass or seals.

Scheduled maintenance is minimal but meaningful. Visual inspections once or twice a year catch loose conduit straps, cracked roof sealant, or wildlife nesting around arrays. Inverter fans and heat sinks should be free of debris. If your production suddenly dips, check for tripped breakers, internet outages affecting data, or shading from a newly grown branch. Module failures are uncommon, but electronics can age: inverter replacements are a normal lifecycle event, often covered by warranty if within term. Keep records of serial numbers, installation dates, and warranty documents so claims are straightforward.

Insurance and documentation deserve attention. Notify your home insurer after installation; many policies cover rooftop solar as part of the dwelling, but limits and deductibles vary. Some jurisdictions offer property‑tax relief for added solar value, and some studies have found that owned systems can correlate with higher resale prices, though the premium depends on market awareness, age of the system, and transferability of warranties. If you plan to sell, keep a binder—or digital folder—of plans, approvals, and performance history to reassure buyers.

– Revisit your utility tariff annually; rate structures evolve and can change savings patterns.

– Consider complementary upgrades: smart thermostats, heat pump water heaters, or EV charging can increase solar self‑consumption.

– Assess battery additions if outages are common or if time‑of‑use windows shift value into evening hours.

– Explore community education or neighborhood co‑ops to share lessons learned and reduce soft costs for others.

Conclusion: Solar rewards patient, informed decision‑making. Start with a realistic site assessment, choose equipment that matches your goals, and insist on transparent numbers. If the economics and roof conditions align, a residential system can quietly deliver reliable kilowatt‑hours for decades while increasing your home’s resilience. With a clear plan and steady follow‑through, you can turn sunlight into a confident, measurable upgrade for your household.