Garage Door Repair: System Troubleshooting and Repair Guide

System Overview, Safety, and Reader’s Outline

Quick outline to help you navigate:

– Components and how they work together

– Mechanical diagnostics: balance, tracks, rollers, hardware

– Electrical and controls: openers, sensors, limits, remotes

– Repair procedures you can do and when to call a pro

– Preventive maintenance, budgeting, and long-term reliability

A reliable garage door protects vehicles, buffers weather, and quietly anchors home security. It’s a counterbalanced machine that may lift well over a hundred pounds thousands of times during its life, so problems ripple into daily routines fast. Springs are typically rated for 10,000–20,000 cycles; with two trips a day, that can be as little as 7–10 years. Understanding how the system works—and where hazards reside—turns guesswork into a clear plan.

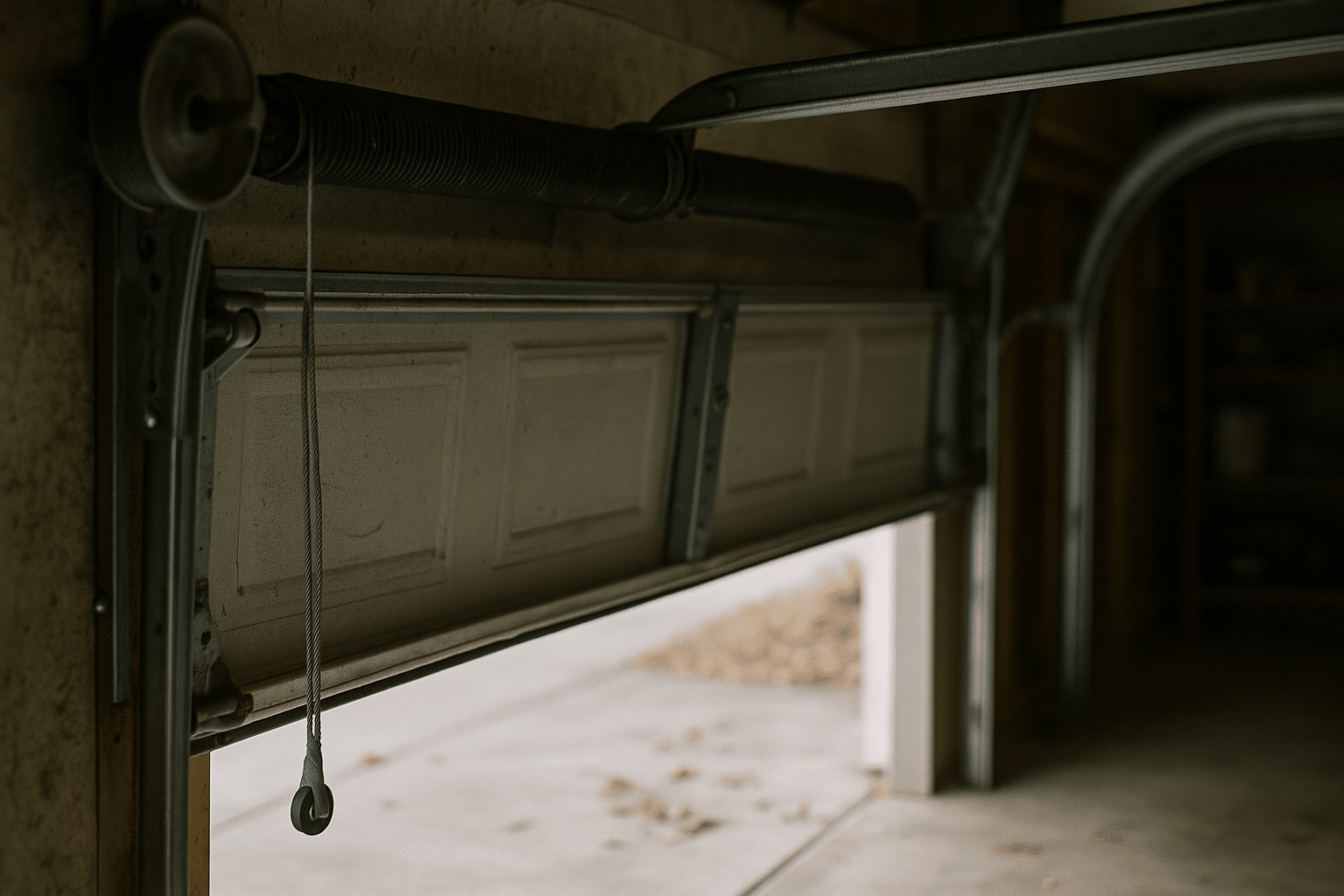

At its core, the door’s weight is offset by a counterbalance: torsion springs on a shaft above the opening or extension springs stretching along the tracks. Drums on the shaft wind cables attached to the bottom brackets, lifting the door panels along rollers guided by vertical and horizontal tracks. Hinges let the panels articulate, while struts stiffen wide sections. The opener isn’t a crane; it’s a helper that moves a properly balanced door along a rail. When balance is right, a person can lift the door by hand with steady, moderate effort.

Safety is not optional. Torsion springs and wound cables store serious energy; uncontrolled release can cause severe injury. Follow these principles:

– Unplug the opener before mechanical work and use the manual release with the door fully closed.

– Never loosen set screws on torsion hardware or remove bottom brackets with cables attached.

– Use locking pliers or clamps to secure the door to the track when working at mid-height.

– Keep hands clear of pinch points around hinges and section seams.

– Never bypass photoelectric sensors or defeat reversal features.

Respect these boundaries, and the rest of the system becomes approachable, calm, and fixable.

Mechanical Diagnostics: Balance, Tracks, and Hardware

Start with the simplest and most revealing test: balance. Pull the opener’s manual release when the door is fully closed. Lift the door to knee height, then waist, then chest; a well-balanced door stays roughly in place at each point with only minor drift. If it sags to the floor, the springs may be under-tensioned; if it wants to shoot up, they may be over-tensioned. Either condition increases opener strain and accelerates wear on gears, trolleys, and rails.

Friction leaves clues. Roll the door by hand and listen: scraping suggests track rub; pops often point to cracked hinges; rough rumble can be flat-spotted or dry rollers. Tracks should be plumb and parallel; horizontal sections need a slight back pitch so the door rests against the stop molding when fully open. The track spacing should match door thickness plus a small allowance so rollers sit centered—too tight binds the rollers, too loose lets the door rattle.

Inspect these wear points methodically:

– Rollers: Nylon wheels tend to be quieter; steel wheels tolerate heat better and can be more durable with sealed bearings. Wobble, chipped edges, or exposed bearings are replacement signs.

– Hinges: Hairline cracks at the knuckle or elongated screw holes weaken panel joints; replace at the first sign to prevent panel damage.

– Cables: Frayed strands near the bottom bracket indicate fatigue; if you see broken wires, stop operating and call a pro—those cables are under spring tension.

– Panels: Dents near hinge stiles and end stiles can cause binding; minor bends may be reinforced with a strut, while creases across a full panel often require section replacement.

– Weather seals: Brittle top or bottom seals admit water and wind that can freeze tracks and corrode hardware.

Compare systems to sharpen the diagnosis:

– Torsion vs. extension springs: Torsion offers smoother balance and less bounce; extension springs must have safety cables to contain breakage.

– Nylon vs. steel rollers: Nylon reduces noise and vibration; steel handles exposure, but needs lubrication.

– Single vs. double doors: Double doors magnify misalignment; small track errors that a single door tolerates can jam a wider span.

– Insulated vs. non‑insulated: Added weight from insulation demands accurate spring sizing; a heavy door that was upgraded after installation may never have been rebalanced.

Document what you find. A quick photo of a cracked hinge or a measurement of track offset taken today will keep your repair plan grounded and protect you from chasing new noises that are unrelated to the root cause.

Electrical and Controls: Openers, Sensors, and Logic

Once mechanics check out, turn to the electrical side. Confirm power first: test the outlet with a lamp, reset any tripped GFCI upstream, and examine the opener’s plug for heat discoloration. If the opener hums but nothing moves, the trolley may be disengaged or a travel limit set too far; if the lights flash and the door won’t close, sensors are the primary suspect.

Photoelectric safety sensors should sit a few inches above the floor, facing each other with lenses clean and brackets unbent. Most sensors display a solid indicator when aligned; a flicker or dark LED suggests misalignment, wiring damage, or obstruction. Common culprits include stored items brushing a lens, cobwebs, or a kicked bracket. Sun glare can sometimes overwhelm a lens at certain angles; slight bracket adjustment and clean lenses usually solve it. Never tape a sensor to force operation; that defeats required safety features and risks injury.

Travel and force settings translate motion limits into safe stops. If the door reverses just as it touches the floor, the down travel may be set too far, causing the opener to detect resistance; reduce the down limit slightly and retest. Excessive force is not a shortcut to reliability; it masks problems and can damage panels. Perform the reversal test with a flat piece of lumber under the door: the door should reverse promptly upon contact, satisfying modern safety standards that require automatic reversing.

Drive types influence behavior:

– Chain drives: Durable and tolerant of temperature swings; they require periodic tensioning and can be louder.

– Belt drives: Quieter and smoother; belts should be tightened to remove slack without bowstringing.

– Screw or direct drives: Fewer moving parts; they benefit from periodic lubrication compatible with the rail design.

Radio issues can arise when certain bulbs generate interference; if remote range shrinks after swapping bulbs, try a different non‑interfering bulb type and route the opener’s antenna straight down and unobstructed.

Use this quick control checklist:

– Wall console: Ensure it isn’t in “lock” mode; a small indicator often shows status.

– Remotes and keypads: Replace batteries in sets and reprogram if memory was cleared by a power surge.

– Wiring: Tug gently at low‑voltage connections; a single loose strand can intermittently disable sensors or the wall control.

– Trolley and release: Verify the manual release re‑engages; pull the release toward the opener and run the motor to reconnect the carriage to the trolley.

Repairs You Can Do: Step-by-Step Fixes and When to Call a Pro

Many common problems are approachable with patience, basic tools, and respect for safety boundaries. Begin by tightening hardware: with the door closed, use a nut driver or socket to snug hinge bolts and track brackets. Do not overtighten; you’re looking for firm and flush. Where fasteners have chewed into wood jambs, add longer lag screws into fresh material or install a structural backing board.

Lubrication calms friction and noise. Apply a light, non‑drip lubricant to steel roller bearings, hinge pins, and torsion spring coils; wipe away excess to avoid attracting grit. Avoid spraying tracks directly—clean them instead with a dry cloth so rollers roll instead of slide. For screw or specific rail designs, use the lubricant recommended for that mechanism.

Track alignment cures many jams. With the door clamped partially open to remove pressure, slightly loosen the bolts on the track brackets. Nudge the track so the rollers sit centered with a paper‑thin clearance and re‑tighten. Vertical tracks should be plumb; horizontal tracks should angle gently upward toward the rear to hold the door open without drifting.

Roller and hinge replacement can be done one piece at a time. Keep the door secured with locking pliers on the track. Swap mid‑section rollers by removing the hinge bolts, replacing the hinge and roller as an assembly, and reinstalling. Do not remove the bottom roller bracket; it anchors the lift cable, which is under spring tension. Replace any hinge with visible cracks or distorted holes to prevent panel damage from spreading.

Opener adjustments are straightforward when performed incrementally:

– Set down and up travel so the door seals firmly at the floor without crushing, and opens fully without hitting the stops.

– Adjust force just enough to operate smoothly on a balanced door; retest the reversal function after each change.

– Tension a loose chain or belt to eliminate sag but avoid overtightening.

– Align sensors until their indicators are steady and the door closes without hesitation.

Know when to call a professional. Tasks involving torsion springs, lift cables, drums, center bearing plates, and bottom brackets carry high stored energy and specialized procedures. Bent shafts, severe panel creases across the full width, and doors that have jumped the cable also warrant expert help. Typical market ranges vary by region, but as a rough orientation: a comprehensive tune‑up may fall in the low hundreds, torsion spring replacement often lands in the mid hundreds depending on door weight and spring count, cable replacements and track resets are commonly below that, and full opener replacements depend on drive type and features. Clear photos and notes from your diagnostics will help a technician quote accurately.

Preventive Maintenance, Costs, and Long‑Term Reliability

Preventive care keeps surprises at bay and stretches the life of every component. Follow a simple schedule:

– Monthly: Visual check for frayed cables, loose fasteners, cracked hinges, and sensor alignment.

– Quarterly: Clean tracks, lubricate moving metal parts, and wipe sensor lenses.

– Twice yearly: Test balance with the opener disconnected, and perform a safe reversal test with a flat piece of lumber on the floor.

– Yearly: Inspect weather seals and top astragal, tighten header and track fasteners, and check the opener rail supports.

Small upgrades can yield quiet, steady operation:

– Nylon rollers with sealed bearings reduce noise and need fewer top‑offs of lubricant.

– A strut across the top panel prevents bowing on wide doors, especially where an opener attaches.

– High‑cycle spring options match homes with frequent use, reducing the frequency of replacements over the years.

– Surge protection shields control boards from voltage spikes, while battery backup preserves access during outages.

– Fresh side and top seals improve comfort and can help manage dust and drafts in attached garages.

Budget with a long view. Spending a little on annual care—lubricants, seals, and an occasional roller—can postpone larger expenses by reducing wear on springs and openers. Keep receipts and a simple log of adjustments and part replacements; this record helps with warranty claims and makes conversations with service providers efficient. When hiring, look for transparent pricing, proof of insurance, and written estimates that specify parts, labor, and warranty terms. Ask for explanations of spring sizing and cycle ratings so the solution fits your door’s weight and your household’s usage.

Practical habits round out reliability:

– Keep the area around the sensors and tracks clear of storage items.

– Address water intrusion that can rust bottom fixtures and freeze door bottoms to the slab.

– Replace hardened bottom seals before they gouge the floor or stress the opener at closure.

– Listen to your door; a new sound is an early signal, not background noise.

Conclusion

A garage door is a disciplined machine that rewards steady care. By learning how balance, tracks, rollers, sensors, and controls interact, you can diagnose confidently, handle sensible repairs, and choose professional help wisely when high‑energy parts are involved. Treat the door like the moving wall it is, and it will repay you with quiet, predictable service through early mornings, late returns, and every season in between.