Generator Installation: A Professional Guide to Backup Power Solutions

Outline:

– Backup options and sizing basics

– Site assessment, permits, and code compliance

– Electrical integration and transfer switches

– Fuel choices, storage, and runtime economics

– Professional installation workflow, testing, and maintenance

Backup Options and Sizing Basics

When the sky growls and the room dims, the right generator feels less like a machine and more like insurance against chaos. Choosing that machine begins with understanding the two broad families: portable and standby. Portable units (including quieter inverter models) are mobile, cost-effective, and suited for essential loads. Standby systems are permanently installed, start automatically, and can support most or all circuits, making them well-regarded for homes and small businesses that can’t afford downtime.

Think of sizing as the backbone of this decision. Start by listing essential loads: refrigerator (600–800W running, higher on start), sump pump (800–1,500W with a surge several times higher), gas furnace blower (400–800W), lights (variable), and networking gear (50–100W). Motors can require 3–7x starting current, so prioritize surge demands. A practical approach: calculate running watts, add 20–30% for headroom, and verify starting watt capacity. For many households, 5–8 kW portable systems cover essentials, while 10–24 kW standby systems can operate most circuits, depending on the home’s size and load behavior.

Noise and power quality matter, too. Inverter portables often sit around 50–60 dBA at partial load and produce cleaner sine waves, friendly to electronics. Open-frame models can reach 70–80 dBA, suitable outdoors but less neighborly. Standby units use sound-dampened enclosures and maintain stable voltage and frequency under varying loads. Fuel efficiency also changes with load: a small gasoline portable might consume around 0.4–0.8 gallons per hour at 50% load, whereas residential standby units at similar load might draw roughly 100–200 cubic feet of natural gas per hour or about 0.5–1.2 gallons of propane per hour, depending on capacity and tuning.

Budget ranges vary by scale and site conditions. As broad, non-binding estimates: portable systems can run a few hundred to a few thousand dollars, while a complete standby solution (equipment, transfer gear, pad, fuel connections, permits, and professional installation) can reach into the five-figure range. The payoff is measured in continuity: keeping heat, refrigeration, medical devices, point-of-sale terminals, or remote workstations online when the grid goes quiet.

Quick checklist for early planning:

– List essential and nice-to-have loads with running and starting watts

– Decide if automatic operation is important

– Consider acceptable noise levels and fuel availability

– Sketch a budget range aligned with risk tolerance

Site Assessment, Permits, and Code Compliance

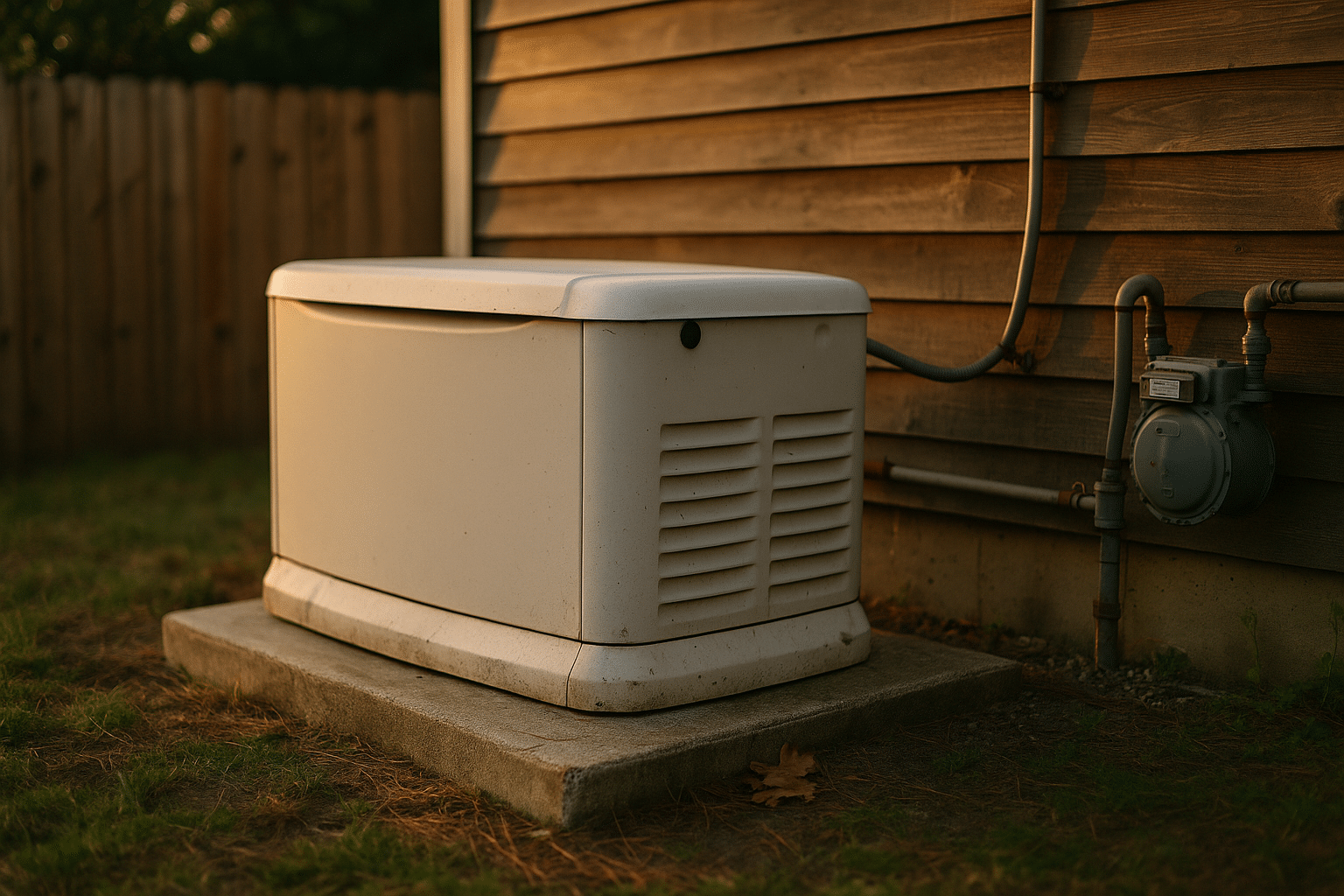

A smart installation begins outdoors with a tape measure and a level head. Placement affects safety, longevity, and code approvals. Choose a stable, non-flood-prone spot with good airflow and room for service access. Common guidelines call for keeping the generator several feet from windows, doors, and vents to reduce carbon monoxide risk; many jurisdictions and manufacturers specify minimum clearances that often start around 5 feet from openings and property lines, but your local authority having jurisdiction (AHJ) and the manufacturer’s manual take precedence.

Ground preparation is straightforward but important. A compacted gravel base topped with a reinforced concrete pad keeps the enclosure level and resists frost heave, vibration, and wind. Conduits for power, control wiring, and, if applicable, gas piping should be routed cleanly with sweep bends to protect cables and maintain serviceability. Corrosion-resistant materials, drip loops, and weather-tight fittings help the installation age gracefully through rain, heat, and winter’s bite.

Permitting is not bureaucracy for its own sake; it is the framework that prevents dangerous shortcuts. Expect separate permits for electrical and fuel gas work (propane or natural gas), and sometimes zoning review if you’re in a designated district. Inspectors typically validate conductor sizing, overcurrent protection, transfer equipment type, working clearances, and bonding/grounding. For stationary units, local code often references national standards covering engine installations, ventilation, and exhaust routing; installers coordinate with utility providers for meter sizing or regulator adjustments if the generator will share the natural gas service.

Plan for the real world:

– Floodplain and drainage: avoid pooling water and ice dams

– Snow loads and drifting: maintain clear exhaust paths

– Vegetation: allow space around louvers and keep shrubs trimmed

– Sound: consider neighbors and reflective walls that amplify noise

– Access: leave room for oil changes, filter swaps, and diagnostics

Document everything. Good proposals include site sketches, load lists, equipment schedules, and a one-line diagram of how the generator ties into your electrical system. Clear drawings accelerate approvals and reduce surprise costs mid-project. A thoughtful site assessment sets the stage for a compliant, durable installation that your inspector—and your future self—will appreciate.

Electrical Integration: Transfer Switches, Load Management, and Wiring

Electricity behaves beautifully when given clear boundaries, and the transfer switch is the referee. Its job is to ensure your generator and the utility never energize the same conductors at once, eliminating backfeed hazards that endanger lineworkers and equipment. There are three common strategies: manual transfer switches for portable units, interlock kits where permitted to backfeed a panel through a dedicated inlet and breaker, and automatic transfer switches paired with standby generators to detect outages and switch power seamlessly.

Manual transfer switches usually feed a small emergency subpanel. You select which circuits are energized, then start the generator and flip the switch. Interlock kits, when approved by the AHJ, occupy less space and can cost less, but they require disciplined operation and labeling. Automatic transfer switches (ATS) monitor utility voltage; when the grid falls out of tolerance, the ATS starts the generator, waits for it to stabilize, and transfers load—often within seconds. For whole-home coverage, service-entrance-rated ATS units incorporate overcurrent protection and meet service equipment requirements.

Load management is the difference between smooth sailing and nuisance trips. Modern systems can shed heavy loads—like electric water heaters or HVAC compressors—when generator capacity is strained, then restore them as headroom returns. This allows a smaller generator to comfortably support a larger house. Coordinate neutral handling carefully: some generators have bonded neutrals, others are floating; the transfer equipment must maintain a single neutral-to-ground bond in the system to avoid shock hazards and stray currents. Label everything clearly so future service work remains safe and intuitive.

Wiring fundamentals still rule:

– Conductor sizing follows ampacity tables and temperature ratings

– Copper lugs should match conductor type and gauge

– Conduit fill, bend radius, and support intervals affect reliability

– GFCI and AFCI protection requirements remain in force for applicable circuits

For portable setups, a 120/240V, 30A or 50A inlet mounted outdoors with a properly rated power cord is typical; weatherproof covers and strain relief protect connections. For standby systems, control wiring between the ATS and generator carries start/stop signals and status; low-voltage conductors must be separated from power conductors per code. Finally, test under load. Verify voltage, frequency, and transfer timing, and use a clamp meter to confirm real currents rather than guessing by sound. Safe integration is an orchestration of parts working to a single, well-documented plan.

Fuel Choices, Storage, and Runtime Economics

Fuel is where theory meets the long night of an outage. Each option—gasoline, propane, natural gas, diesel—has trade-offs in storage, availability, emissions, and cost per kilowatt-hour delivered. If you’re after convenience, natural gas and large propane tanks shine because they avoid last-minute fuel runs. If you favor energy density and long runtimes, diesel is compelling, especially at larger scales. Gasoline is widely available for portables but degrades over time without stabilizers and demands careful storage practices.

Quick comparisons:

– Gasoline: easy to find, higher volatility, short storage life without additives

– Propane: clean burning, stable in storage, requires cylinders or bulk tank

– Natural gas: continuous supply when utilities remain pressurized, requires utility connection

– Diesel: high energy density, good efficiency, heavier equipment, cold-weather considerations

Consumption varies by size and load. A mid-size inverter portable at half load might sip 0.2–0.4 gallons of gasoline per hour. Residential standby units in the 10–20 kW range can draw roughly 0.5–1.2 gallons of propane per hour at moderate load, or 100–250 cubic feet of natural gas per hour. Diesel sets scale differently: larger units often deliver more kW per gallon than small gasoline engines. The delivered cost of electricity from a generator spans a wide range, often from about $0.50 to well over $2.00 per kWh, depending on fuel price, generator efficiency, and how heavily it is loaded. Running closer to 60–80% of rated capacity typically improves efficiency compared to idling along at very light loads.

Storage strategy matters as much as price. Rotate gasoline stock every few months or treat with stabilizer, and store in approved containers away from living spaces. Propane cylinders should be upright, outdoors, and inspected for valve condition and date stamps; bulk tanks require proper setback and regulator sizing. Natural gas requires coordination with the utility for meter capacity; some sites need upgraded regulators to handle generator demand without starving appliances. Diesel must be kept clean and dry; water in the tank encourages microbial growth that clogs filters. Fuel logs—date, quantity, and runtime—turn guesswork into planning.

Finally, think holistically. If you live where ice storms are routine and roads close, on-site fuel reserves are valuable. If pipelines are dependable in your region, natural gas’s continuous supply reduces storage headaches. The right choice is the one that keeps your critical loads humming with the least drama when the weather and the grid conspire against you.

Professional Installation Workflow, Testing, and Maintenance

A polished installation follows a predictable arc: consult, design, permit, install, commission, and maintain. During consultation, you’ll review outage history, the critical-load list, and noise or space constraints. The design phase yields a one-line diagram, equipment schedules, and an installation plan that anticipates trenching, concrete, gas piping, and panel work. Permitting formalizes the plan; inspections ensure the system is safe and documented for future owners, insurers, and service technicians.

On installation day, the crew sets the pad, places the generator, routes conduit, and lands conductors. Gas fitters size and install piping or connect propane regulators and tanks; electricians mount the transfer switch, reroute circuits, and label everything. Then comes commissioning: fuel and oil checks, initial start, voltage/frequency tuning, and a live transfer test. A thorough handover includes a walkthrough of controls, shutdown procedures, fault codes, and maintenance intervals, plus an emergency checklist that can be taped near the equipment.

What happens after the celebratory moment when the lights stay on during a test? Maintenance. Internal combustion engines crave routine:

– Oil and filter changes at hour-based intervals (often 50–150 hours for portables, 100–200 hours for many air-cooled standby units, per manuals)

– Air filter inspections to protect against dust and pollen

– Spark plug checks (gasoline/propane) or fuel system care (diesel)

– Battery testing and replacement on a predictable cycle

– Exercise runs weekly or monthly to keep seals lubricated and verify readiness

Consider ownership costs over a 5–10 year horizon. Portable systems have lower upfront costs but rely on manual fueling and cord management; they’re ideal for essentials and occasional outages. Standby systems add convenience and coverage at a higher price, offset by reduced disruption during longer blackouts. Budget not only for equipment but also for professional maintenance, periodic testing, and potential upgrades such as load-shedding modules or additional fuel storage. Keep a binder—permits, diagrams, invoices, and a log of run hours and maintenance—to turn your installation into a managed asset rather than a mystery box.

The final quality check is behavioral: run a dress rehearsal when the weather is good. Start the generator, transfer load, verify that refrigerators, furnaces, and critical circuits behave as expected, and confirm that sensitive electronics see stable voltage. Outages are less intimidating when you’ve already practiced the playbook.

Conclusion: Choosing Peace of Mind Over Panic

Backup power isn’t about chasing outages; it’s about refusing to be defined by them. Whether you’re protecting a family, a home office, or a small storefront, a properly sized generator, installed with permits and tested under load, turns uncertainty into routine. Pick the fuel that fits your region, the switchgear that fits your habits, and the maintenance plan that fits your calendar. Then, when the grid stumbles, your lights, heat, and business keep their stride.