Wooden Fence Installation and Care Guide

Outline and Planning Essentials

Before you sink a single post, a clear plan pays dividends. Here is the outline you will follow as you read, then apply:

– Choosing materials and styles to match climate, code, and purpose

– Site preparation, layout, and safe installation steps

– Finishing, weatherproofing, and aesthetic upgrades

– Maintenance routines, repairs, and cost of ownership

– A practical wrap-up to help you move from idea to completed fence

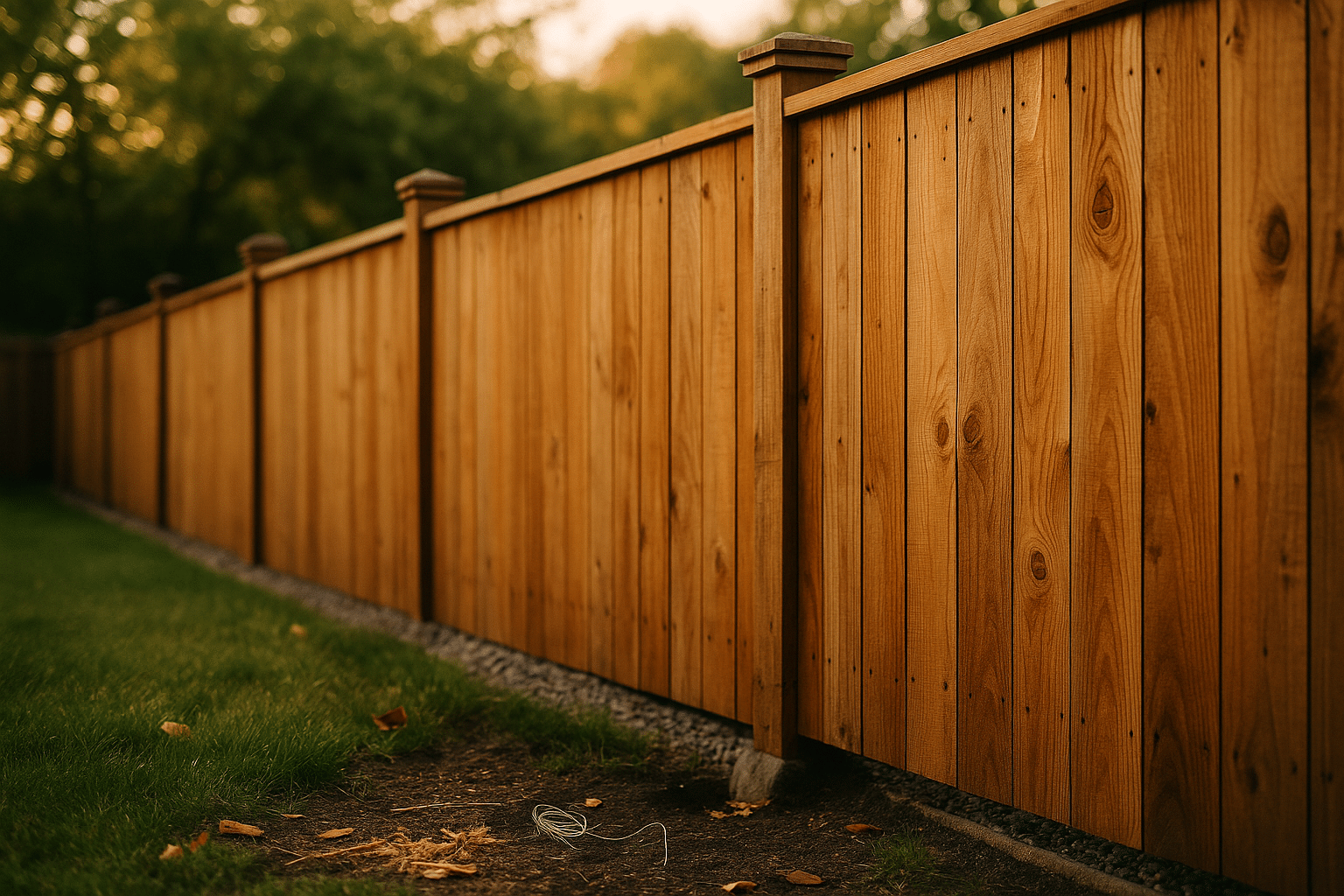

A well-built wooden fence starts long before the first hole. Confirm your property lines with a recent survey or recorded plat, and have a quick conversation with adjacent property owners to avoid future disputes. Many municipalities require permits, height limitations (often 3–4 ft in front yards and 6–8 ft in backyards), and rules for corner visibility near streets. In frost-prone regions, expect footing depths to extend below the frost line; in warmer zones, the common rule of thumb is post embedment at roughly one-third of above-ground height.

Plan your layout around how the fence will be used, not just how it will look. A privacy run needs tight picket spacing and sturdy rails; a decorative garden edge can be lighter. Think about slope: racked panels follow grade smoothly, while stepped sections create level tiers on hillsides. Place gates where people naturally walk, with at least one gate wide enough for a wheelbarrow or mower (usually 36–48 in). Long, uninterrupted runs benefit from occasional jogs or posts set to stiffen the line in windy areas.

Prepare a sketch with lengths, post spacing (commonly 6–8 ft), gate locations, and elevation changes. Use a linear materials takeoff to estimate posts, rails, pickets or panels, concrete or gravel, fasteners, and finish. Also budget time: a two-person crew often spends a full weekend on 100–150 linear feet, not including finishing. A planning checklist can help:

– Call utility locators before digging

– Order materials early to allow acclimation

– Verify disposal plan for excavated soil

– Stage tools so installation flows without delays

Good planning sets expectations and reduces mid-project improvisation. It also clarifies what “finished” looks like: consistent post height, clean sight lines, and components placed to shed water. With the outline in hand, you are ready to choose wood that fits your climate and goals.

Choosing Wood Species and Fence Styles

Wood selection determines how your fence weathers, how often it needs care, and how it handles fasteners over time. Common choices include cedar, pine, redwood, cypress, and spruce. As a general guide, approximate Janka hardness values range from around 350 lbf for western cedar and 380 lbf for spruce, to 450 lbf for many redwoods, 510 lbf for cypress, and 600–700 lbf for southern yellow pine. Hardness affects dent resistance, while natural durability depends on the species and whether you are using heartwood or sapwood. Heartwood in species like redwood and cedar contains compounds that resist decay better than their sapwood.

Climate is a major filter. In rainy or humid regions, naturally decay-resistant species or pressure-treated options extend service life, especially for posts and bottom rails. In dry, high-UV regions, lighter woods may weather faster without a UV-blocking finish but often remain structurally sound; choosing a penetrating stain helps preserve color. In coastal areas, salt air increases corrosion, so pair your wood with stainless or heavily galvanized fasteners to avoid black staining and premature metal failure.

Fence style shapes performance as much as appearance. Privacy designs with tight picket spacing excel at screening but catch wind; to compensate, use thicker posts, deeper footings, and closer spans. Shadowbox or board-on-board patterns allow airflow while still blurring sight lines. Picket fences define property edges and keep pets in yet maintain neighborhood openness. Horizontal fences are visually striking but place greater emphasis on straight, stable boards; choose straighter grades and consider back rails that prevent sag.

Think through structural elements and details:

– Post size and spacing: 4×4 is common; upgrade to 6×6 for tall or wind-exposed runs

– Rails: two rails for short fences, three for taller or privacy designs

– Ground clearance: leave roughly 2 in between pickets and soil to limit splashback and rot

– Caps and trim: post caps, cap rails, and kick boards help redirect water and protect end grain

Local codes and neighborhood guidelines may guide height and street-side appearance. If noise reduction is a goal, mass helps: thicker boards, board-on-board layouts, and limited gaps perform better than thin, gapped pickets. For wildlife or pet considerations, adjust spacing and choose hardware cloth at the base where burrowing is an issue. With species and style chosen, you can move confidently to site prep and installation steps.

Site Preparation, Tools, and Step-by-Step Installation

Good installation is about accuracy and consistency. Gather tools so workflow is smooth:

– Measuring tape, stake flags, and mason’s line for layout

– Post hole digger or auger, digging bar, and shovel for footings

– Level, speed square, and string line levels for alignment

– Circular or hand saw, drill/driver, and bits for cutting and fasteners

– Safety glasses, hearing protection, gloves, and dust mask for personal safety

– Wheelbarrow, mixing tub, and hoe for setting posts if using concrete

Start with a straight, well-tensioned layout. Set corner and gate posts first, using batter boards and string to define lines. Mark post locations at 6–8 ft intervals, adjusting for panel widths. Dig holes to at least one-third of the fence height or below frost depth in cold climates. A bell-shaped footing resists uplift and sway; add a few inches of compacted gravel at the bottom for drainage. Set a post, align to the string, and brace it plumb in both directions. Backfill with concrete or compacted gravel: concrete offers rigidity, while well-compacted gravel drains and allows replacement with less demolition. Crown the top of the footing away from the post to shed water.

Install rails level or to follow the grade, depending on style. Fasten rails to posts with corrosion-resistant screws or structural brackets, ensuring consistent spacing that will support your pickets or panels. Attach pickets with a small, even gap for expansion; pre-drill near board ends to avoid splitting, especially with dense or dry stock. Keep the bottom edges about 2 in above soil to reduce moisture contact. For gates, upgrade to heavier posts and diagonal bracing within the gate frame to prevent sag; hang the gate so the latch meets squarely and swings freely.

Work methodically:

– Continuously check plumb and level; small errors compound over distance

– Stagger joints in rails for strength and cleaner sight lines

– Use stainless or hot-dip galvanized fasteners to resist rust and staining

– Trim post tops to a uniform height and add caps to protect end grain

Safety and quality go together. Keep utilities marked and stay clear by recommended distances. Lift with legs, not your back, and take breaks to maintain attention. At day’s end, police the site: remove offcuts, collect nails and screws, and protect fresh concrete from pets and rain. A tidy jobsite not only looks professional but also prevents accidental damage before finishing.

Finishing and Weatherproofing: Stain, Paint, and Hardware Choices

Finish is both armor and artistry. Wood outdoors faces ultraviolet light, moisture cycles, and temperature swings that cause checking and color shift. Penetrating stains soak into fibers and leave a breathable surface; film-forming coatings like paint or solid-color stains create a protective layer that can look uniform but require attentive maintenance if peeling begins. Transparent and semi-transparent stains showcase grain and typically need recoating every 2–4 years, while solid-color finishes often stretch to 4–7 years, depending on climate and sun exposure.

Timing matters. Fresh pressure-treated lumber contains moisture that slows finish absorption; allow boards to air-dry until a water drop beads and soaks in slowly rather than sitting on the surface. As a loose rule, many projects benefit from a few weeks to a couple of months of drying, but the water-bead test is more reliable than the calendar. Aim for dry, mild weather with no rain forecast for at least 24 hours after application and temperatures in a moderate range so curing proceeds evenly.

Application technique will influence durability as much as product choice. Back-brush after spraying to drive finish into pores and even out lap marks. Two thin coats usually outperform one heavy coat. Seal end grain on posts, rails, and cut picket tops; end grain behaves like a bundle of straws and absorbs water rapidly. Maintain a small gap between boards to allow drainage and airflow, and avoid sealing the bottom edge tightly against grade. If you prefer paint, prime knots where needed and consider a stain-blocking undercoat to reduce bleed-through.

Hardware deserves the same attention. Use stainless steel or hot-dip galvanized fasteners; avoid plain steel, which leaves dark streaks as tannins react with rust. In coastal or industrial areas, stainless often repays the small premium by resisting corrosion longer. Hinges and latches should be matched to gate weight and mounted with through-bolts where possible. Add post caps to keep water out, and consider a cap rail to protect picket end grain. Small details help shed water: a slight chamfer on horizontal edges, drip edges under cap rails, and sloped gate braces that move water away from joints.

Environmental considerations are part of modern finishing. Lower-VOC, water-based stains have improved significantly and are easier to clean up; oil-modified options can penetrate deeply and lend rich color. Whichever you choose, read coverage rates and plan enough material for two coats on sun-exposed faces. With a smart finish, your fence holds its shape, keeps its color, and needs only periodic light maintenance instead of costly overhauls.

Maintenance, Repairs, and Total Cost of Ownership

A wooden fence rewards consistent, simple care. A seasonal routine catches small issues before they become structural repairs. In spring, rinse off road salts, pollen, and winter grime. In summer, watch for drying checks and hardware loosening as wood shrinks. Autumn is a good time to clear leaf piles and organic debris that trap moisture against boards and posts. After major storms, scan for leaning posts, lifted footings, and fasteners that have backed out.

Cleaning is gentle but purposeful. Use a garden hose, soft brush, and an oxygenated cleaner according to label instructions to lift mildew and dirt. Avoid harsh bleaching that can soften fibers. If using a pressure washer, stay conservative: a wide fan tip, low to moderate pressure (around 1,000–1,500 psi), and a distance of at least 12–18 in reduces the chance of furring and gouging. After washing, let the fence dry thoroughly before touch-up staining or painting.

Repairs fall into predictable categories:

– Loose fasteners: replace with stainless or hot-dip galvanized screws; pre-drill near edges

– Split or cupped pickets: swap out individual boards and reseal cut edges

– Sagging gates: re-square with an adjustable brace and upgrade hinges or fasteners

– Wobbly posts: diagnose whether decay, shallow footing, or soil movement is to blame; re-set in new footings or add a larger footing collar to stabilize

Post longevity is critical because posts are hardest to replace. Keep soil and mulch pulled back a couple of inches from posts to reduce constant wetting. If rot is localized near grade, a careful excavation and addition of drainage gravel plus a sloped concrete collar can extend life. In termite-prone areas, maintain clear inspection zones and avoid burying wood scraps near the fence line. Where animals dig, a narrow strip of buried wire mesh at the base can deter tunneling without trapping moisture against pickets.

Budgeting for the full life cycle makes decisions clearer. Materials-only costs for a wood privacy fence commonly land in a range that varies by species and height, while professional installation adds labor that often brings totals to several tens of dollars per linear foot. Beyond the build, plan for periodic finish re-coats, a small annual hardware allowance, and eventual board or rail replacements. With routine care, many wooden fences provide 15–25 years of service or more, especially when posts are durable and end grain is protected. Think of maintenance as a small annual subscription that preserves a much larger investment.

Conclusion: Build Once, Care Always

Whether you are defining a garden, adding privacy, or securing a pet-friendly yard, a wooden fence offers warmth, character, and practical value. With a clear plan, species and style chosen for your climate, careful installation, and a smart finish, you set the stage for decades of reliable service. Keep a modest seasonal routine, tune up hardware, and refresh the finish on schedule, and the fence will keep doing its job quietly in the background. The result is a boundary that looks intentional from day one and stays that way with a few well-spent hours each year.