Learn more about laser engraving

Introduction to Laser Engraving

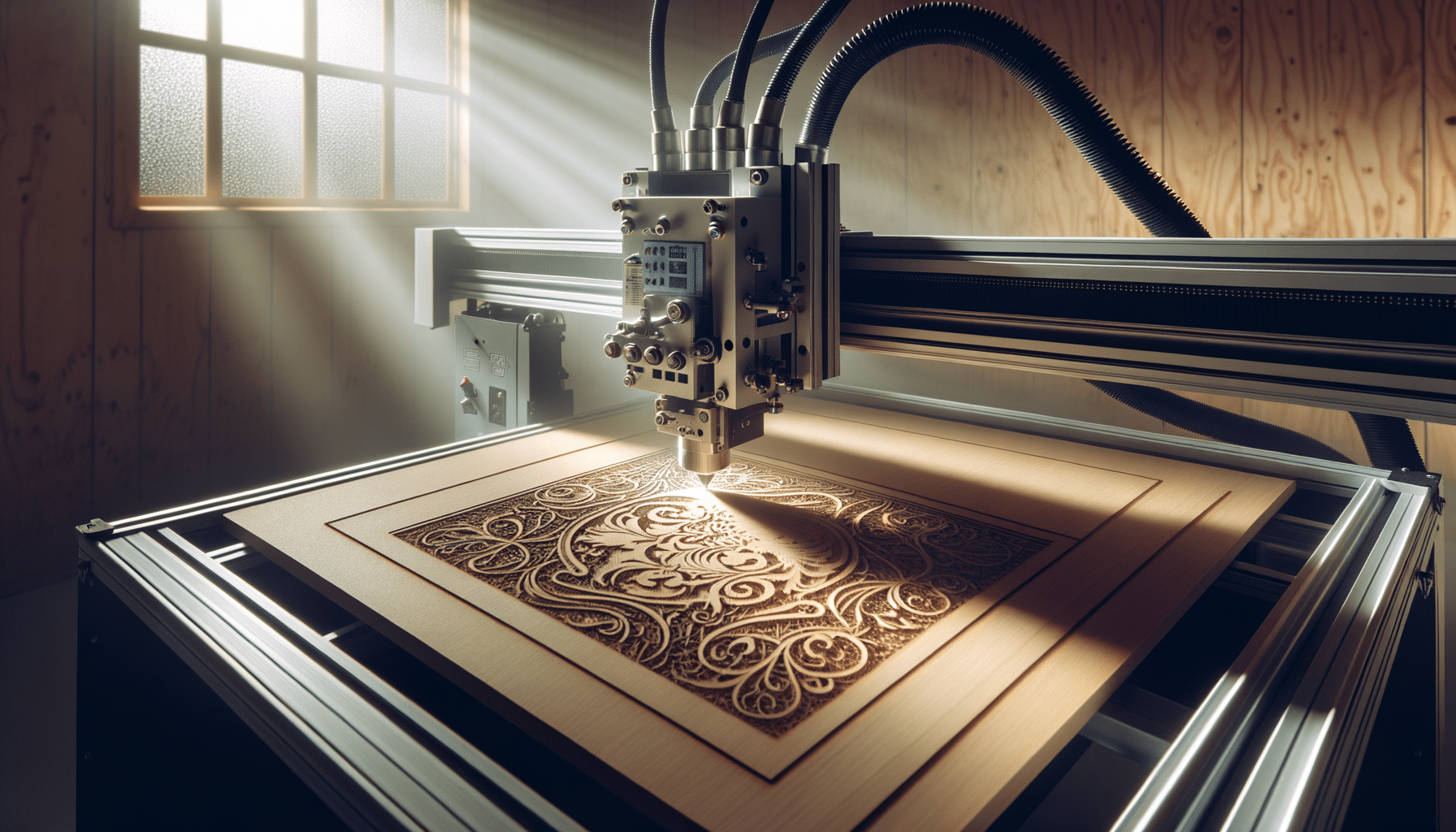

Laser engraving has emerged as a popular method for creating intricate designs on various materials, offering precision and versatility that traditional methods cannot match. This technique uses a laser beam to remove material from the surface of an object, creating permanent marks with great detail. Whether used for industrial applications or personal projects, laser engraving is celebrated for its ability to produce high-quality results with minimal waste.

The Mechanics of Laser Engraving

Understanding the mechanics behind laser engraving is crucial to appreciating its capabilities. A laser engraving machine consists of a laser source, a controller, and a surface to engrave. The laser source generates a high-intensity beam directed by mirrors and lenses to focus on the surface. The controller manages the movement of the laser, allowing for precise designs. By adjusting the intensity, speed, and focus of the laser, different effects can be achieved on a variety of materials, such as wood, metal, glass, and plastic.

Laser engraving is classified into three main types: vector engraving, raster engraving, and cutting. Vector engraving follows the path of lines in a vector graphic, while raster engraving fills in areas much like a printer. Cutting goes through the material, creating shapes and patterns. Each type offers unique advantages depending on the project’s requirements, making laser engraving a versatile choice for many applications.

Applications of Laser Engraving

Laser engraving finds applications across numerous industries due to its precision and adaptability. In manufacturing, it is used for marking parts with serial numbers, barcodes, and logos, ensuring traceability and branding. The jewelry industry employs laser engraving for personalizing pieces with names and dates, adding sentimental value to items. Additionally, laser engraving is prominent in the creation of awards and trophies, where intricate designs and text can be engraved onto various surfaces.

Beyond industrial uses, hobbyists and artists embrace laser engraving for crafting custom items. From personalized gifts to intricate art pieces, the possibilities are endless. The technology has also found a place in education, where it is used to teach students about design and engineering principles.

Benefits and Limitations

Laser engraving offers several benefits that make it an attractive option for various applications. One of its primary advantages is precision. The laser’s ability to produce fine details allows for complex designs that are difficult to achieve with other methods. Moreover, laser engraving is a contactless process, reducing wear and tear on tools and materials.

However, laser engraving is not without limitations. The initial cost of laser engraving equipment can be high, making it a significant investment for small businesses or hobbyists. Additionally, not all materials are suitable for laser engraving. Some plastics, for example, can emit harmful fumes when engraved, necessitating proper ventilation and safety measures.

Despite these challenges, the efficiency and quality of laser engraving often outweigh its drawbacks, making it a preferred choice for many users.

Future Trends in Laser Engraving

The future of laser engraving looks promising, with advancements in technology driving new possibilities. One trend is the development of more compact and affordable laser engravers, making the technology accessible to a broader audience. This democratization of laser engraving could lead to increased innovation as more individuals and small businesses explore its potential.

Additionally, advancements in software are enhancing the capabilities of laser engraving machines. Improved design software allows for more complex and intricate patterns, while automation features streamline the engraving process, reducing the time and effort required for each project.

As sustainability becomes increasingly important, laser engraving is also seen as an environmentally friendly option. Its precision reduces material waste, and the contactless nature of the process minimizes the need for disposable tools.

Overall, laser engraving continues to evolve, offering exciting opportunities for creativity and efficiency in various fields.